- Overview

- Product Parameters

- Product Description

- Detailed Photos

- Company Profile

- Certifications

- Packaging & Shipping

- Exihibition

- FAQ

Basic Info.

Packaging & Delivery

Product Description

AC Composite Suspension Insulator

| NO. | Description | Rated Voltage (kV) | Specified Mechanical Tensile Load (kN) | Coupling Size | Section Height H (mm) | Minimum Nominal Arcing Distance H (mm) | Minimum Nominal Creepage DistanceL (mm) | Lightning Impulse Withstand Voltag≥(kV) | Wet Switching Impulse Withstand Voltage≥(kV) | Wet Power Frequency Withstand Voltage≥(kV) |

| 1 | FXBW-11/70 | 11 | 70 | 16 | 400±5 | 230 | 630 | 110 | - | 40 |

| 2 | FXBW-11/100 | 11 | 100 | 16 | 400±5 | 228 | 630 | 110 | - | 40 |

| 3 | FXBW3-33/70 | 33 | 70 | 16 | 610±15 | 445 | 1100 | 240 | - | 100 |

| 4 | FXBW4-33/70 | 33 | 70 | 16 | 650±15 | 484 | 1140 | 240 | - | 100 |

| 5 | FXBW-33/100(120) | 33 | 100(120) | 16 | 650±15 | 454 | 1285 | 240 | - | 100 |

| 6 | FXBW3-66/70 | 66 | 70 | 16 | 870±15 | 710 | 2100 | 410 | - | 185 |

| 7 | FXBW4-66/70 | 66 | 70 | 16 | 940±15 | 750 | 2170 | 410 | - | 185 |

| 8 | FXBW-66/100(120) | 66 | 100(120) | 16 | 940±15 | 750 | 2420 | 410 | - | 185 |

| 9 | FXBW3-110/70 | 110 | 70 | 16 | 1180±15 | 1024 | 3310 | 550 | - | 230 |

| 10 | FXBW4-110/70 | 110 | 70 | 16 | 1240±15 | 1084 | 3370 | 550 | - | 230 |

| 11 | FXBW3-110/100(120) | 110 | 100(120) | 16 | 1180±15 | 1004 | 3260 | 550 | - | 230 |

| 12 | FXBW4-110/100(120) | 110 | 100(120) | 16 | 1240±15 | 1054 | 3300 | 550 | - | 230 |

| 13 | FXBW-110/300 | 110 | 300 | 24 | 1480±15 | 1123 | 3266 | 550 | - | 230 |

| 14 | FXBW3-220/100(120) | 220 | 100(120) | 16 | 2150±30 | 1964 | 6400 | 1000 | - | 395 |

| 15 | FXBW4-220/100(120) | 220 | 100(120) | 16 | 2240±30 | 2049 | 6650 | 1000 | - | 395 |

| 16 | FXBW3-220/160(180) | 220 | 160(180) | 20 | 2150±30 | 1904 | 6810 | 1000 | - | 395 |

| 17 | FXBW4-220/160(180) | 220 | 160(180) | 20 | 2240±30 | 1980 | 7100 | 1000 | - | 395 |

| 18 | FXBW-220/210(240) | 220 | 210(240) | 20 | 2300±30 | 1979 | 7090 | 1000 | - | 395 |

| 19 | FXBW-220/300 | 220 | 300 | 24 | 2350±30 | 2001 | 6905 | 1000 | - | 395 |

| 20 | FXBW3-330/100(120) | 330 | 100(120) | 16 | 2930±40 | 2725 | 9660 | 1425 | 950 | 570 |

| 21 | FXBW4-330/100(120) | 330 | 100(120) | 16 | 2990±40 | 2804 | 10120 | 1425 | 950 | 570 |

| 22 | FXBW3-330/160(180) | 330 | 160(180) | 20 | 2930±40 | 2654 | 9033 | 1425 | 950 | 570 |

| 23 | FXBW4-330/160(180) | 330 | 160(180) | 20 | 2990±40 | 2714 | 9250 | 1425 | 950 | 570 |

| 24 | FXBW3-330/210(240) | 330 | 210(240) | 20 | 2930±40 | 2614 | 9150 | 1425 | 950 | 570 |

| 25 | FXBW4-330/210(240) | 330 | 210(240) | 20 | 2990±40 | 2674 | 9200 | 1425 | 950 | 570 |

| 26 | FXBW-330/300 | 330 | 300 | 24 | 2930±40 | 2579 | 8680 | 1425 | 950 | 570 |

| 27 | FXBW3-500/100(120) | 500 | 100(120) | 16 | 4030±50 | 3805 | 13500 | 2050 | 1240 | 740 |

| 28 | FXBW4-500/100(120) | 500 | 100(120) | 16 | 4450±50 | 4217 | 16600 | 2250 | 1240 | 740 |

| 29 | FXBW3-500/160(180) | 500 | 160(180) | 20 | 4030±50 | 3714 | 13450 | 2050 | 1240 | 740 |

| 30 | FXBW4-500/160(180) | 500 | 160(180) | 20 | 4450±50 | 4174 | 15100 | 2250 | 1240 | 740 |

| 31 | FXBW3-500/210(240) | 500 | 210(240) | 20 | 4030±50 | 3714 | 13450 | 2050 | 1240 | 740 |

| 32 | FXBW4-500/210(240) | 500 | 210(240) | 20 | 4450±50 | 4134 | 14850 | 2250 | 1240 | 740 |

| 33 | FXBW3-500/300 | 500 | 300 | 24 | 4030±50 | 3639 | 12900 | 2050 | 1240 | 740 |

| 34 | FXBW4-500/300 | 500 | 300 | 24 | 4450±50 | 4059 | 14150 | 2250 | 1240 | 740 |

| 35 | FXBW3-500/400(420) | 500 | 400 | 28 | 4030±50 | 3630 | 14832 | 2050 | 1240 | 740 |

| 36 | FXBW4-500/530(550) | 500 | 530 | 32 | 4450±50 | 3957 | 15300 | 2250 | 1240 | 740 |

| 37 | FXBW-750/100(120) | 750 | 100(120) | 16 | 7150±50 | 6930 | 23500 | 2700 | 1800 | 740 |

| 38 | FXBW-750/160(180) | 750 | 160(180) | 20 | 7150±50 | 6800 | 23500 | 2700 | 1800 | 740 |

| 39 | FXBW-750/210(240) | 750 | 210(240) | 20 | 7150±50 | 6800 | 23500 | 2700 | 1800 | 740 |

| 40 | FXBW-750/300 | 750 | 300 | 24 | 7150±50 | 6735 | 23500 | 2700 | 1800 | 740 |

| 41 | FXBW-750/400(420) | 750 | 400(420) | 28 | 7150±50 | 6730 | 23500 | 2700 | 1800 | 740 |

| 42 | FXBW-750/530(550) | 750 | 530(550) | 32 | 7150±50 | 6625 | 23500 | 2700 | 1800 | 740 |

| 43 | FXBW-1000/160(180) | 1000 | 160(180) | 20 | 9500±50 | 9150 | 27500 | 2400 | 1800 | 1300 |

| 44 | FXBW-1000/210(240) | 1000 | 210(240) | 20 | 9500±50 | 9150 | 27500 | 2400 | 1800 | 1300 |

| 45 | FXBW-1000/300 | 1000 | 300 | 24 | 9500±50 | 9115 | 27500 | 2400 | 1800 | 1300 |

| 46 | FXBW-1000/400(420) | 1000 | 400(420) | 28 | 9500±50 | 9075 | 27500 | 2400 | 1800 | 1300 |

| 47 | FXBW-1000/530(550) | 1000 | 530(550) | 32 | 9500±50 | 8975 | 27500 | 2400 | 1800 | 1300 |

| 48 | FXBW-1000/160(180)-S | 1000 | 160(180) | 20 | 9800±50 | 9200 | 27500 | 2400 | 1800 | 1300 |

| 49 | FXBW-1000/210(240)-S | 1000 | 210(240) | 20 | 9900±50 | 9200 | 27500 | 2400 | 1800 | 1300 |

| 50 | FXBW-1000/530(550)-S | 1000 | 530(550) | 32 | 10000±50 | 8950 | 27500 | 2400 | 1800 | 1300 |

DC Composite Suspension Insulator

| NO. | Description | Rated Voltage (kV) | Specified Mechanical Tensile Load (kN) | Coupling Size | Section Height H (mm) | Minimum Nominal Arcing Distance H (mm) | Minimum Nominal Creepage DistanceL (mm) | Lightning Impulse Withstand Voltag≥(kV) | Wet Switching Impulse Withstand Voltage≥(kV) | Wet Power Frequency Withstand Voltage≥(kV) |

| 1 | FXBZ-±400/160(180) | ±400 | 160(180) | 20 | 8000±50 | 7600 | 26000 | 2800 | 1800 | 750 |

| 2 | FXBZ-±400/210(240) | ±400 | 210(240) | 20 | 8000±50 | 7600 | 26000 | 2800 | 1800 | 750 |

| 3 | FXBZ-±400/300 | ±400 | 300 | 24 | 8000±50 | 7600 | 26000 | 2800 | 1800 | 750 |

| 4 | FXBZ-±400/400(420) | ±400 | 400(420) | 28 | 8000±50 | 7600 | 26000 | 2800 | 1800 | 750 |

| 5 | FXBZ-±400/530(550) | ±400 | 530(550) | 32 | 8000±50 | 7500 | 26000 | 2250 | 1150 | 600 |

| 6 | FXBZ-±500/160(180) | ±500 | 160(180) | 20 | 5440±50 | 5070 | 20500 | 2250 | 1550 | 600 |

| 7 | FXBZ-±500/210(240) | ±500 | 210(240) | 20 | 5440±50 | 5070 | 20500 | 2250 | 1550 | 600 |

| 8 | FXBZ-±500/300 | ±500 | 300 | 24 | 5440±50 | 5040 | 20500 | 2250 | 1550 | 600 |

| 9 | FXBZ-±500/400(420) | ±500 | 400(420) | 28 | 5440±50 | 4950 | 20500 | 2250 | 1550 | 600 |

| 10 | FXBZ-±500/530(550) | ±500 | 530(550) | 32 | 5440±50 | 4900 | 20500 | 2250 | 1550 | 600 |

| 11 | FXBZ-±500/160(180) | ±500 | 160(180) | 20 | 6000±50 | 5630 | 20500 | 2250 | 1550 | 600 |

| 12 | FXBZ-±500/210(240) | ±500 | 210(240) | 20 | 6000±50 | 5630 | 20500 | 2250 | 1550 | 600 |

| 13 | FXBZ-±500/300 | ±500 | 300 | 24 | 6000±50 | 5600 | 20500 | 2250 | 1550 | 600 |

| 14 | FXBZ-±500/400(420) | ±500 | 400(420) | 28 | 6000±50 | 5510 | 20500 | 2250 | 1550 | 600 |

| 15 | FXBZ-±500/530(550) | ±500 | 530(550) | 32 | 6000±50 | 5500 | 20500 | 2250 | 1550 | 600 |

| 16 | FXBZ-±660/160(180) | ±660 | 160(180) | 20 | 8500±50 | 8100 | 33400 | 2800 | 1800 | 750 |

| 17 | FXBZ-±660/210(240) | ±660 | 210(240) | 20 | 8500±50 | 8100 | 33400 | 2800 | 1800 | 750 |

Notes:

Notes: 1. The color can be customized.

2. Below 220kV electrical data shown for composite line post insulators without corona rings and mounted vertically. Wuhan Line Power recommends corona rings to be installed at 220kV and above.

3. Additional section lengths and creepage distances are available. Contact sales agency for details.

4. All dimensions, tolerances and tests are within allowable IEC standards or ANSI standards.

5. All dimensions are in millimeters(mm). If in inches and pounds, please specify.

6. We can design according to the end user's requirements.

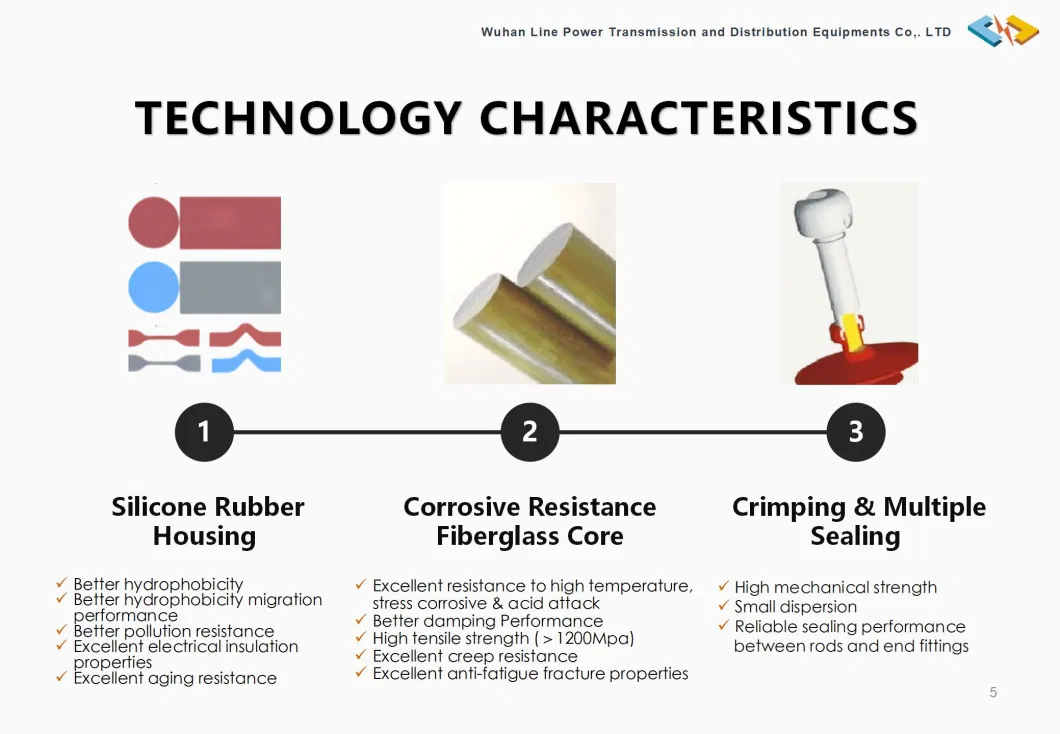

Raw Materials

| End Fittings | Core | Sheds and Housing |

| Hot dip galvanized cast iron or cast steel | Epoxy & Glass fiber(ECR is available) | HTV Silicone Rubber |

| Min. thickness of the galvanization: 86μm | Diameter(mm): Φ38, Φ40, Φ55, Φ70, Φ90, Φ120 | Color: Grey, Red |

Our company with strong strength, reasonable price, good service and a number of enterprises to establish a long-term partnership. With high quality products and perfect after-sales service, we have won the consistent reputation of customers all over the country. We sincerely welcome customers from home and abroad to visit, investigate and discuss business cooperation.

Advanced Manufacturing Equipments

The company holds the most advanced Automatic Silicone Injection Molding Machines and Voice-operated Displacement Crimping Machines which means the world's most advanced process technology level.

The company holds the most advanced Automatic Silicone Injection Molding Machines and Voice-operated Displacement Crimping Machines which means the world's most advanced process technology level. Sound Testing Equipment

The company is equipped with 1000kV Power Frequency Testing Transformer, 1800kV Impulse Voltage Generator set and 2000kN Automatic Tensile Test Machine, as well as well-equipped Physical Laboratory and Electrical Laboratory.

Standards:

IEC 61109, ISO 9001, ISO 14001, ISO 45001. We can design products in accordance with Client's Requirements.

We have implemented advanced management and set up a strict quality management system according 1- 1509001 : 200S. All the products' quality requirements comply with IEC61109, IEC62231, G3/T19519-2004,GE/T 22079-200s, DU/T 1048-2007.DL/T810-2002 and TE/T3199.2-200g Standards, etc.

We have implemented advanced management and set up a strict quality management system according 1- 1509001 : 200S. All the products' quality requirements comply with IEC61109, IEC62231, G3/T19519-2004,GE/T 22079-200s, DU/T 1048-2007.DL/T810-2002 and TE/T3199.2-200g Standards, etc. 1. All composite insulators are packed in weatherproof containers in order to protect the products during land, air, and sea transportation. Several different grades of packaging can be offered depending on the mode of transport and the expected storage conditions. The packaging options that we offer are

1) standard grade/prefabricated packing

2) economical grade/cardboard carton

3) best grade/closed wooden crate

Since the user best knows their crate requirements, they should select the option that is most suited to their needs and include that information in the purchasing specification. Special packaging arrangements can be accommodated upon request.

2. Each container is marked with the number of insulators it contains, the catalog number, the manufacturer's name, and any other customer requests.

3. Each packing (wooden Cases or Paper ubes) attached specification and certification of products.

We have been participating in various exhibitions at home and abroad from 2010 to 2020. At the exhibition, relevant people from the industry and us saw our products directly and closely.

1. Q: Are you the factory or trading company?

A: We are factory who was founded in 2008. We also source all the items for the clients.

2. Q: What're your main products?

A: insulators, the hardware of all kinds for high-voltage applications and related products.

3. Q: Can I get some samples?

A: Yes, sample order is available for quality check and market test.

4. Q: What's your payment terms?

A: We usually accept :Payment Term: 30% T/T after order confirmed, balance 70% before shipment. L/C is also available.

5. Q: How can you control your quality?

A: For each production processing, we have a complete QC system for the chemical composition, physical and electrical properties. After production, all the goods will be tested according to related standards, and the ex-factory test reports will be sent along with shipment documents.

6. Q: Does your company accept customization?

A: We accept OEM service.

7. Q: What's your warranty terms?

A: We offer 24 months warranty terms.

8. Q: Do you have the products in stock?

A: Depends on your request, we have standard models in stock. Some special product and big order will be newly produced according to your order.

9. Q: What do you have for the certificate?

A: ISO9001, ISO14001, ISO45001, Type test etc.

10. Q: How to become the agents for Line?

A: We welcome you to be Line's agent.

We will depend on the sales turn over and also do research on your market. If you have interest, let us discuss more!

11.Q: Can we visit your company?

A: Yes, for sure, you are welcome to visit our company.